Wholesale Dealers of Manual Round Bottle Labeling Machine - Shrink Sleeve Labeling Machine – SINOPAK

Wholesale Dealers of Manual Round Bottle Labeling Machine - Shrink Sleeve Labeling Machine – SINOPAK Detail:

1. Characteristics

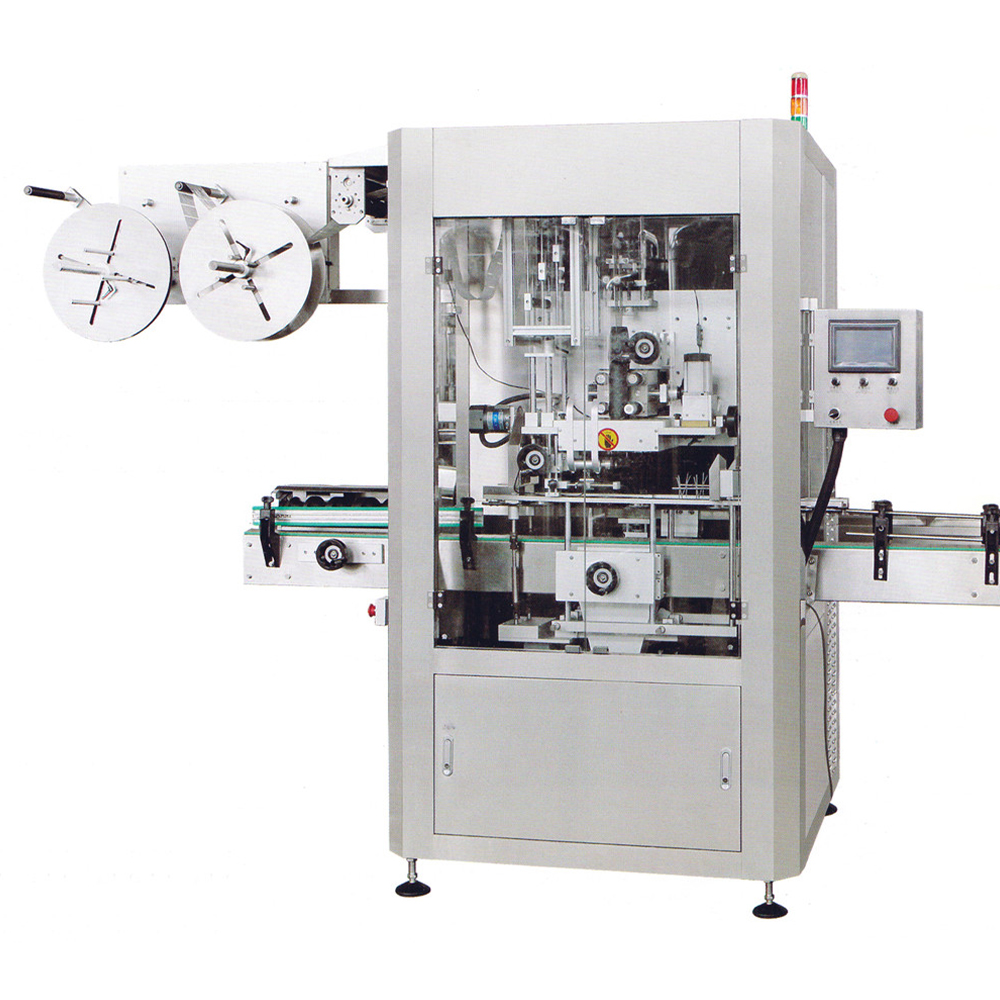

☆ The whole machine adopts stainless steel and high-quality aluminum, well-structured, compact and easy to adjust.

☆ Without anchor bolts can be easily mobile, flexible space with the production.

☆ Shrink film label rack, with adjustable brake, and paper tube according to label 5 “~ 10″ to facilitate adjustment.

☆ Unique set of standard methods, the use of compression-type sets of tender, in a convenient and reasonable.

☆ Automatic feed motors, at the same time leveling materials shrink film tension adjustment.

☆ Volume label detection system ensure that the minimum error.

☆ Unique design of the knife is special in the framework, can change blocks ATC freely, ATC quickly and easily.

☆ Center column clamping system, change quickly and without any tools.

☆ Label positioning device, according to the demand for container shape, position adjustment can be synchronized movements.

☆ Hours bottle-screw, positioning belt, chain adjustment using synchronous manner, and speed adjustment is simple, quick.

☆ Adopt Japanese servo motor and high-sensitivity photoelectric, standard length is precision.

☆ Stainless steel electrical control box, control the use of Japan’s Mitsubishi PLC.

☆ Adopt advanced automatic control technology of the man-machine interface, the key electrical components are adopted internationally renowned products.

|

Main technical parameters of the equipment |

|||||

|

Model |

SL-100 |

SL-200 |

SL-300 |

SL-400 |

SL-500 |

|

Voltage |

AC220V, 50/60HZ, 1.5-2KW (Host machine) AC380V,50/60HZ, 18KW (Shrinking machine) |

AC220V, 50/60HZ, 1.5 KW (Host machine) AC380V,50/60HZ, 18KW (Shrinking machine) |

AC220V, 50/60HZ, 2.5 KW (Host machine) AC380V,50/60HZ, 24KW (Shrinking machine) |

AC220V, 50/60HZ, 3 KW (Host machine) AC380V,50/60HZ, 36KW (Shrinking machine) |

AC220V, 50/60HZ, 3 KW (Host machine) AC380V,50/60HZ, 36KW (Shrinking machine) |

|

Production speed |

6000 BPH |

9000-12000 BPH |

15000-18000 BPH |

22000-24000 BPH |

28000-30000 BPH |

|

Diameter of bottle body |

∮28mm-∮125mm |

∮28mm-∮125mm |

∮28mm-∮125mm |

∮28mm-∮125mm |

∮28mm-∮125mm |

|

Length of label |

30mm-250mm |

30mm-250mm |

30mm-250mm |

30mm-250mm |

30mm-250mm |

|

Thickness of label |

0.035mm-0.13mm |

0.03mm-0.13mm |

0.03mm-0.13mm |

0.03mm-0.13mm |

0.03mm-0.13mm |

|

Material of label |

PVC、 PET、 OPS |

PVC、 PET、 OPS |

PVC、 PET、 OPS |

PVC、 PET、 OPS |

PVC、 PET、 OPS |

|

Size (label sleeving host machine) |

L2000mm*W850mm* H2000mm |

L780mm*W1200mm* H2000mm |

L2100mm*W1100mm*H2000mm |

L2100mm*W850mm* H2000mm |

L2500mm*W1200mm*H2000mm |

|

Size(Bulk of steam shrinking label) |

L1800mm*W500mm* H1500mm |

L1800mm*W500mm* H1500mm |

L1800mm*W500mm* H1500mm |

L1800mm*W500mm* H1500mm |

L1800mm*W500mm* H1500mm |

|

Steam shrinking tunnel (quantity of steam) |

20Kg/H |

30Kg/H |

30Kg/H |

50Kg/H |

50Kg/H |

|

List of Standard electricl appliance Configuration |

|||||

|

Module name |

Electric appliance name |

Type |

Quantity |

Merchant |

Place of production |

|

Machine frame fluctuation unit |

Low power a-c dynamo |

5IK90GU-CF-5GU30KB |

1 |

TWT |

Taiwan |

|

Clean-down unit |

Low power a-c dynamo |

5IK120A-CFT |

1 |

TWT |

Taiwan |

|

Feeding unit |

Low power a-c dynamo |

RV50-15K-180 |

1 |

TWT |

Taiwan |

|

|

Frequency converter |

VFO-0.25KW |

1 |

Panasonic |

Japan |

|

|

Photoelectricity inductor |

CX-421 |

1 |

Panasonic |

Japan |

|

Bottle Carrying unit |

Low power a-c dynamo |

5IK90GN-YFT-5GN20K |

1 |

TWT |

Taiwan |

|

|

Frequency converter |

VFO-0.25KW |

1 |

Panasonic |

Japan |

|

Bottle Separation unit |

Low power a-c dynamo |

5IK90GN-YF-5GN10K |

1 |

TWT |

Taiwan |

|

|

Frequency converter |

VFO-0.25KW |

1 |

Panasonic |

Japan |

|

Hairbrush unit |

Low power a-c dynamo |

4IK25GN-CFT-4GN3K |

2 |

TWT |

Taiwan |

|

Cutter head unit |

Cutter head servo motor |

MHMD042P1U(400w) |

1 |

Panasonic |

Japan |

|

|

Cutter head servo driver |

MBDDT2210003(400w) |

1 |

Panasonic |

Japan |

|

|

Minitype photoelectricity inductor |

PM-L44 |

2 |

Panasonic |

Japan |

|

Driving unit |

Driving servo motor |

MHMD042P1U(400w) |

1 |

Panasonic |

Japan |

|

|

Driving servo driver |

MBDDT2210003(400w) |

1 |

Panasonic |

Japan |

|

Electric eye unit |

High speed fibre-optical inductor |

FX-301 |

1 |

Panasonic |

Japan |

|

Bottle monitor unit |

Photoelectricity inductor |

CX-442 |

1 |

Panasonic |

Japan |

|

Conveyor unit |

Frequency converter |

VFO-0.75KW |

1 |

Panasonic |

Japan |

Product detail pictures:

Related Product Guide:

abide by the contract, conforms into the market requirement, joins in the market competition by its good quality also as provides a lot more comprehensive and great company for purchasers to let them turn into huge winner. The pursue from the firm, would be the clients' gratification for Wholesale Dealers of Manual Round Bottle Labeling Machine - Shrink Sleeve Labeling Machine – SINOPAK , The product will supply to all over the world, such as: South Korea, Germany, Mecca, Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part solutions. Our advantage is full category, high quality and competitive price! Based on that, our products win a high admiration both at home and abroad.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.