Quality Inspection for Mineral Water Bottle Packing Machine - Automatic Drinking Water 3-5 Gallon Filling Machine – SINOPAK

Quality Inspection for Mineral Water Bottle Packing Machine - Automatic Drinking Water 3-5 Gallon Filling Machine – SINOPAK Detail:

The line equips with water spraying device in order to ensure those caps sterile and clean, it also can automatically carry out barrel, washing,sterilizing, filling,capping, counting and products discharging, with complete function, modern design and high degree of automation. It is a new kind of barreled water auto producing line, which integrates mechanism, electricity and pneumatics technologies together.

The 5-gallon water production line consists of empty bottle transfer, inner bottle brushing, automatic cap removal, outer bottle brushing, rinsing, filling and capping, light inspection machine, necking machine, bagging, full bottle transfer, and palletizing machine to achieve fully automatic and intelligent production. The whole process is strictly controlled to ensure full compliance with the customer’s local standards and the regulations set by their health department. Secondary contamination is strictly controlled during the filling process, which makes it an ultra-clean line. This is one of the most ideal, recognized, and reliable automatic gallon water production lines for companies and plants. The line is mainly used to fill 3 and 5 gallons of pure or mineral water.

1. The whole process is controlled by a computer or PLC with a high degree of automation.

2. Optional Internet-ready smart plant management software collects, transmits, stores, counts and analyzes real-time data, making remote control and digital production management easy.

3. Optimized technology reduces operating costs by reducing the consumption of water, electricity, and chemical materials.

4. The entire line is designed to fully comply with food safety quality regulations, avoiding dead spots, dead ends, static liquids, threaded joints, etc.

5. Extensive use of adapters, manholes, valves, etc. ensures the safety and easy maintenance.

6. The combination of proven technology and constant innovation ensures stability and reliability.

Name: De-capping machine

Automatic de-capper is the professional equipment for 5 gallon water filling line, especially the filling line that use recycle barrel. It enhances work efficiency remarkably, reduce secondary pollution from manual de-capping greatly and lower labor intensity. The machine is made of stainless steel which is corrosion resistant and easy cleaning. The pneumatic parts are from the famous brand AIRTAC.

Name: External barrel brushing machine

Full Automatic out side Brushing Machine is affiliated production facility for three & five gallons barrel packing production line. For 5 gallons barrel opening and the body of barrel can be brushed. It is especially suitable for producing mineral water, it can effectively eliminate sediment and alga caused by mineral. This machine brushes the bottom, outside surface and inside surface of the barrel, so washing and cleaning effect can be obviously increased. It can greatly reduce second pollution caused by manual brushing and can reduce works labor stress.

Name: Bottle feeding machine

The device employs key components of electrical appliances and metal materials manufactured by name brand factories from home and abroad. It is not only with the advanced technology, high automatization, easy operation and reliable performances as the genuine device from abroad, but also features with small size, small weight and beautiful appearance, anti-corrodibility.

Name: Full automatic washing-filling-capping

Automatic machine stop for power leakage, short circuit, low air pressure and water leakage.

Bottle flush thoroughly.

Precise filling avoid spill and wastage.

High quality of stainless steel used.

Easy operation and maintenance.

Operational function including counter, external washing, user-friendly screen, water heating.

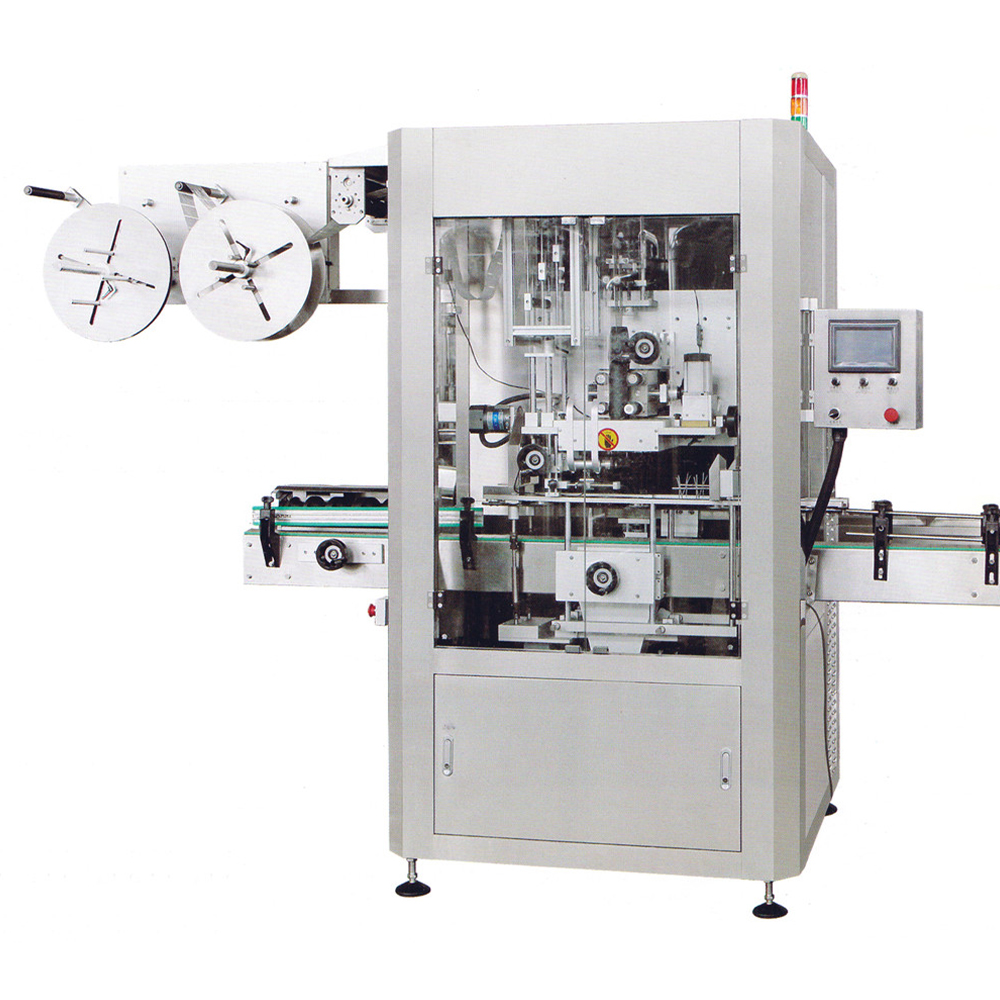

Name:Cap Shrink sleeve labeling Machine

This cap shrink sleeve labeling machine is used to sleeve the plastic label on the 3& 5 gallon caps. It adopted good quality imported stainless steel, simply operation and working smoothly.

Name :Automatic barrel bagging machine

Automatic film feeding, feed, bag, sealing once completed, save manpower, improve efficiency, and realize unmanned operation docking production line. Teflon anti-stick coating alloy thermostatic sealing knife, sealing temperature is extremely sensitive and accurate, it can be arbitrarily set, sealing wire is not easy to crack, no edges, sealing more beautiful.

Name: Palletizer for 3-5 gallon bottle

This machine is auxiliary machine for the final step packaging in 3-5 gallong water production line ,It reduces labor costs.

| Technical parameter :3 -5gallon water filling machine | ||||||

| Model | QGF-100 | QGF-300 | QGF-450 | QGF-600 | QGF-900 | QGF-1200 |

| Capacity (for 5 gallon) | 60-100bph | 300bph | 450bph | 600bph | 900bph | 1200bph |

| Suitable bottle shapes |

PET circular or square |

|||||

| Bottle volume |

3 & 5 Gallon |

|||||

| Compressor air |

0.3-0.7Mpa |

|||||

| Air consumption |

0.37 m3/min |

|||||

| Rinsing pressure |

>0.06Mpa <0.2Mpa |

|||||

| Application |

3 gallon water filling machine |

|||||

| Total power (KW) | 1.5kw | 3.8kw | 4.5kw | 5.2kw | 6.2kw | 7.8kw |

| Overall dimensions | 2.3*1.9m | 2.5*1.9m | 2.8*2.15m | 3.1*2.5m | 3.8*2.8m | 4.5*3.3m |

| Height | 1.8m | 2m | 2.2m | 2.3m | 2.5m | 2.6m |

| Weight(kg) | 800kg | 1500kg | 2000kg | 2500kg | 2800kg | 3500kg |

Product detail pictures:

Related Product Guide:

Control the standard by the details, show the power by quality. Our firm has strived to establish a extremely efficient and stable employees crew and explored an effective excellent command method for Quality Inspection for Mineral Water Bottle Packing Machine - Automatic Drinking Water 3-5 Gallon Filling Machine – SINOPAK , The product will supply to all over the world, such as: Slovakia, New Zealand, Madrid, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.