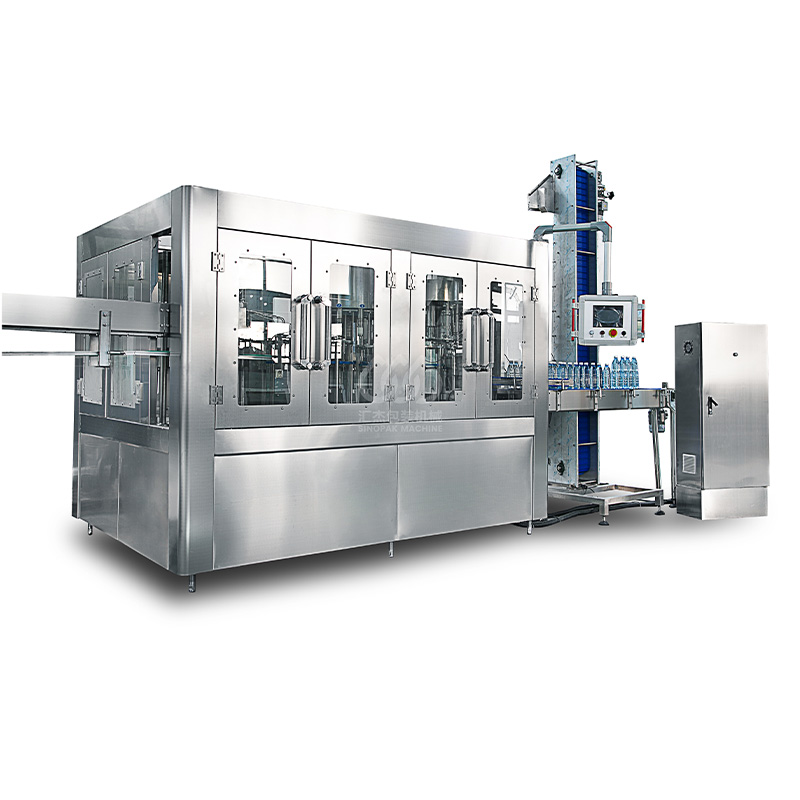

OEM Supply Mineral Water Plant Machinery - Juice mixing blending and preparing system – SINOPAK

OEM Supply Mineral Water Plant Machinery - Juice mixing blending and preparing system – SINOPAK Detail:

Stir, mix, blend, and homogenize the materials. The design structure and configuration can be standardized according to the requirements of the production process. Stirred tank during agitation can be achieved feed control, the feed control, stirring and other manual controls automatic control

The material is refined under the triple action of extrusion, strong impact and loss of pressure expansion, so that the materials can be more uniformly mixed with each other

Function: to homogenize and emulsification the juice and the flavor, syrup together, make them in good taste

1) Tubular UHT is controlled automatically, which considers exterior factors influence on sterilizing temperature, equips high-precision product/water temperature difference control and ensures equipment operation, technical index and material quality PLC control without complicated manual operation and surveillance. It also configures with CIP and SIP system for pre-/after production and can achieve rinsing and sterilizing requirements of equipments.

2) Automatic tubular UHT sterilizes product within a fully-closed system with instant heating and cooling processing, which has less influence on product flavor and nutrition, avoiding second product pollution. Product pumps from closed balance tank, processed by ultra-high temperature, and then cools down to filling temperature, feeding to filler. Heating of product sterilizing uses over-heated water as medium. Filling exit temperature adjustment adopts cooling water as medium with high temperature control precision. All program can be preset according to technics and only needs index on touch screen, and then UHT can be operated according to set program.

3) Ultra-High Temperature plate-type is fully automatic plate which works at the division of general condition. The outer environment to the temperature of sterilization is highly concerned, to ensure the proper operation and quality of materials. For the requirement of hot filling techniques, 3-phase exchanger system is invited to utilize the heat source efficiently and lessen energy consumption. Water is used in both the adjustment of heating of materials and filling temperatures, to get high precise temperature control. All procedures can be designed according to the precondition of actual technics.

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our firm's intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for OEM Supply Mineral Water Plant Machinery - Juice mixing blending and preparing system – SINOPAK , The product will supply to all over the world, such as: Montpellier, Paraguay, South Korea, We have a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.