Leading Manufacturer for 4 Cavity Blow Moulding Machine - PET Bottles Blow Molding Machine – SINOPAK

Leading Manufacturer for 4 Cavity Blow Moulding Machine - PET Bottles Blow Molding Machine – SINOPAK Detail:

1. Energy saving.

2. Easy to operate, just need feeding preform, other work is automatic.

3. Suitable for hot filling, PP, PET bottle blowing.

4. Suitable for different preform neck size, it can change preform jigs very easily.

5. Mold replacement very easily.

6. Oven design in reasonable, adopt blowing-type, water cooling, air cooling all have. Suitable for hot environment to work, the preform neck can’t distortion.

7. The heating lamp adopt infrared quartz lamp, not easy to damager, it is different than semi-auto blowing machine lamp. So it no needs frequently to change lamp. The lamp life is long, even it is broken, it can use also.

8. Our hand feeding stretch blow molding machine can add autoloader+manipulator to became fully automatic.

9. Our machine is more safety and stabilization.

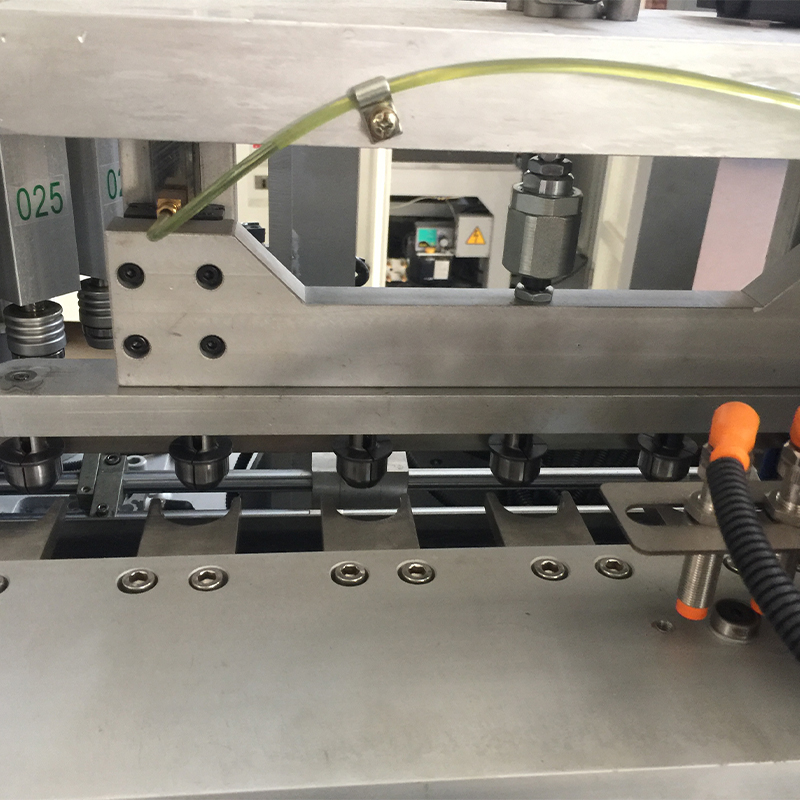

10. Our clamping unit adopts clooked arm configuration self-lubricating system. So very stabilization and no noise.

|

Model |

BL-Z2 |

BL-Z4S |

BL-Z6S |

BL-Z8S |

|

Cavities |

2 |

4 |

6 |

8 |

|

Capacity(BPH) |

2000 |

4000 |

6000 |

8000 |

|

Bottle volume |

100ml-2L(customized) |

|||

|

Body Diameter |

<100mm |

|||

|

Max Bottle Height |

<310mm |

|||

|

Powder |

25KW |

49KW |

73KW |

85KW |

|

Hp air compressor |

2.0m³/min |

4m³/min |

6m³/min |

8m³/min |

|

LP air compressor |

1.0m³/min |

1.6m³/min |

2.0m³/min |

2.0m³/min |

|

Weight |

2000kg |

3600kg |

3800kg |

4500kg |

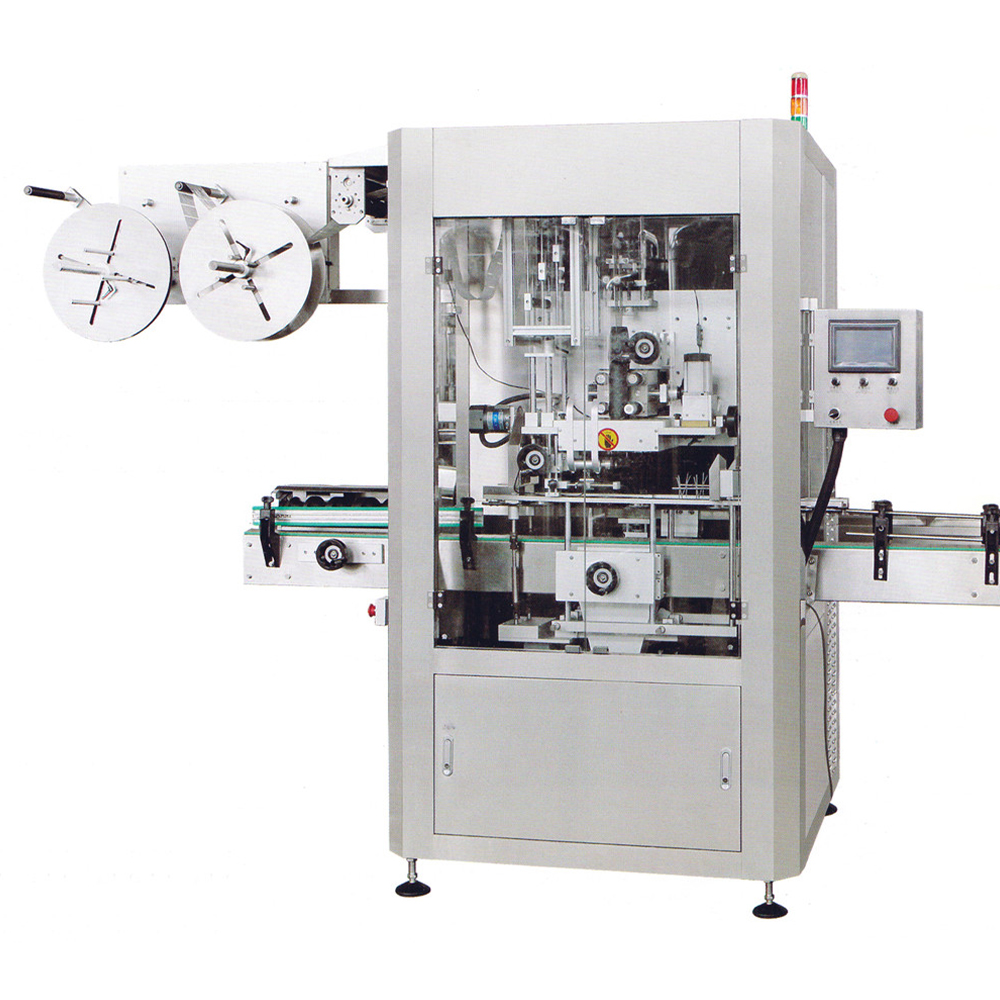

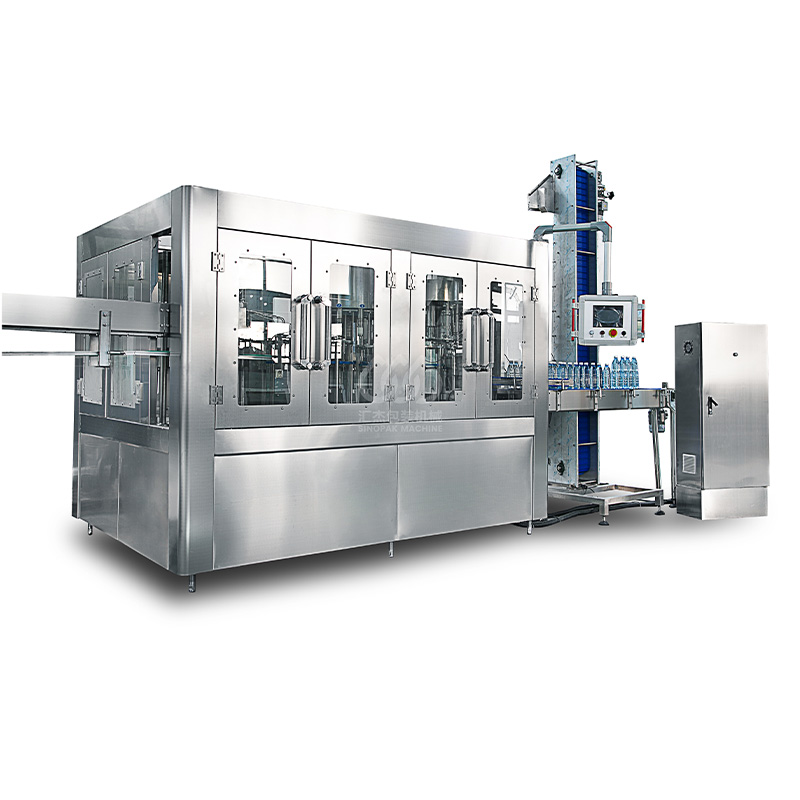

Product detail pictures:

Related Product Guide:

Dedicated to strict top quality command and considerate purchaser support, our experienced staff customers are always available to discuss your necessities and be certain full client gratification for Leading Manufacturer for 4 Cavity Blow Moulding Machine - PET Bottles Blow Molding Machine – SINOPAK , The product will supply to all over the world, such as: Las Vegas, Durban, UAE, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate.

This supplier stick to the principle of Quality first, Honesty as base, it is absolutely to be trust.