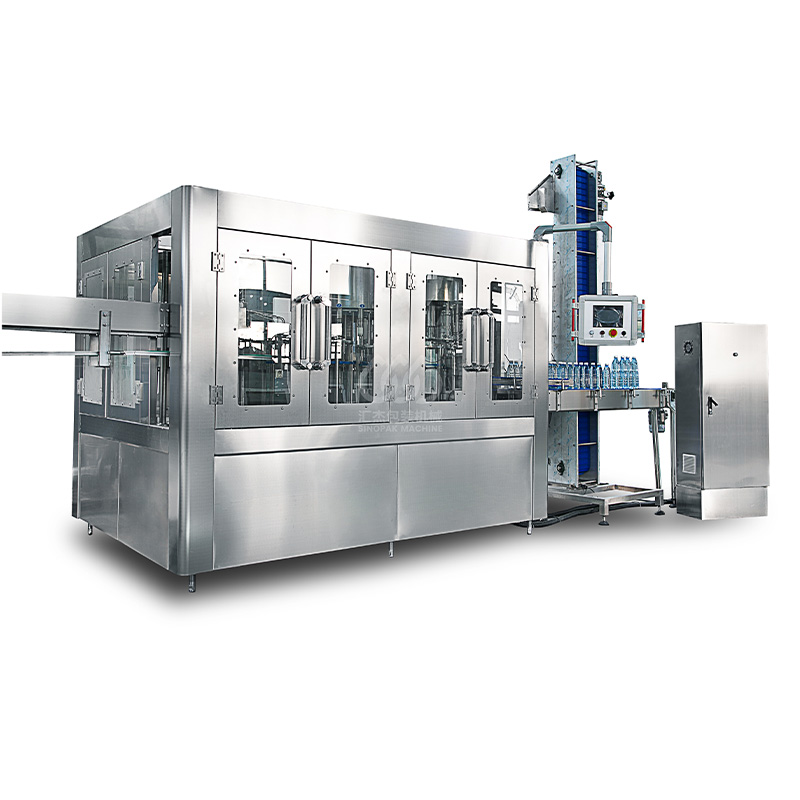

Factory source Water Bottling Plant - Liquid Juice Filling Machine (3 In 1) – SINOPAK

Factory source Water Bottling Plant - Liquid Juice Filling Machine (3 In 1) – SINOPAK Detail:

1. Washing Part:

● Except the down framework, the transmission parts and some parts that must be made of special materials. Other parts are all made of stainless steel 304.

● The roller bearing is made of stainless steel, the sealing ring is made of EPDM material, and plastic is made of UMPE.

● The gripper is made of stainless steel, the position where hold the bottleneck is made of food standard rubber;

● Rinsing time can be guaranteed for 4 seconds.

2. Filling part:

● The entire filler is micro negative pressure filling system .Unique re-flux design saves cost, convenient for external CIP (clean in place)cleaning system.

● High accurate SUS304L construction filling nozzle, make sure high accurate filling level SUS304L liquid bowl, pipeline system .

● Filling level adjustable by choosing different silicone gasket (quick change over parts) No bottles, no filling .

● Butterfly type liquid bowl, with automatic water level controller.

● The hot filling temperature 85-90 degrees, if the temperature is low than the setting value, the filling valves will stop and return the last beverage in filling valve to recycle tank and return to UHT again to sterilize with pump.

3. Capping part:

● Cap distributing chute is equipped with reverse cap stop and reverse cap pick-out mechanism.

● Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute.

● The capper is equipped with inlet bottle detection switch.

● Use waterfall or centrifugal cap cover machine.

|

Project Name:Fruit Juice Hot Filling Machine |

||||||

|

Model |

RXGF 14-12-5 |

RXGF 16-16-5 |

RXGF 24-24-8 |

RXGF 32-32-8 |

RXGF 40-40-10 |

RXGF 50-50-12 |

|

Washing Nos |

14 |

16 |

24 |

32 |

40 |

50 |

|

Filling Nos |

12 |

16 |

24 |

32 |

40 |

50 |

|

Capping Nos |

5 |

5 |

8 |

8 |

10 |

12 |

|

Capacity(BPH) |

3500 |

5000 |

8000 |

12000 |

15000 |

18000 |

|

Suitable bottle |

Glass bottle and PET bottle |

|||||

|

Bottle Volume |

150ml to 2.5Ltr (Customized) |

|||||

|

Bottle diameter(mm) |

Dia50-Dia115 |

|||||

|

Bottle height |

160-320mm |

|||||

|

Compress air pressure(Mpa) |

0.3-0.4 |

|||||

|

Washing medium |

Aspetic water |

|||||

|

Rinsing pressure(Mpa) |

>0.06 <0.2 |

|||||

|

Filling temperature (℃) |

85~90℃ |

|||||

|

Filling theory |

Micro negative pressure filling |

|||||

|

Application |

Fruit juice hot filling machine |

|||||

|

Total powder |

2KW |

2.2KW |

3KW |

4KW |

7.5KW |

7.5KW |

|

Measurement (mm) |

2360*1770*2700 |

2760*2060*2700 |

2800*2330*2700 |

4215*2960*2700 |

4360*3300*2700 |

5900*3300*2700 |

|

Weight |

3200kg |

4000kg |

4500kg |

6500kg |

8000kg |

9500kg |

| No | Name | Brand |

| 1 | Main motor | ABB |

| 2 | Cap unscrambler motor | FEITUO(China) |

| 3 | Conveyor motor | FEITUO(China) |

| 4 | Rinsing pump | CNP (China) |

| 5 | Solenoid valve | FESTO |

| 6 | Cylinder | FESTO |

| 7 | Air-T contactor | FESTO |

| 8 | Pressure adjust valve | FESTO |

| 9 | Inverter | MITSUBISHI |

| 10 | Power switch | MIWE(TAIWAN) |

| 11 | Contactor | SIEMENS |

| 12 | Relay | MITSUBISHI |

| 13 | Transformer | MIWE(TAIWAN) |

| 14 | Approx switch | TURCK |

| 17 | PLC | MITSUBISHI |

| 18 | Touch screen | Pro-face |

| 19 | Air components | FESTO |

| 20 | AC Contactor | Schneider |

| 21 | Micro relay | MITSUBISHI |

1. We are the direct manufacturer, we have been engaged in development and manufacturing of beverages and liquid food filling machines for more than 10 years, our plant area of 6000m2, with independent property rights.

2. We have a professional team for exporting, we can supply stable quality faster delivery and clearly communications.

3. We can make custom manufacturing, our technical team can design different size and products to meet your special requirements.

4. Without getting customer’s approve, we will not ship the equipment hastily, every equipment will be tested continuously 24 hours before loading, we will control every step strictly in the process of manufacture.

5. All of our equipment will have 12 months guarantee, and we will supply techinical servie all equipment life.

6. We will supply the spare parts fast and with cost price.

Product detail pictures:

Related Product Guide:

Our corporation puts emphasis about the administration, the introduction of talented staff, plus the construction of team building, attempting hard to improve the quality and liability consciousness of team members. Our organization successfully attained IS9001 Certification and European CE Certification of Factory source Water Bottling Plant - Liquid Juice Filling Machine (3 In 1) – SINOPAK , The product will supply to all over the world, such as: Thailand, Mali, France, Our company regards reasonable prices, efficient production time and good after-sales service as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.