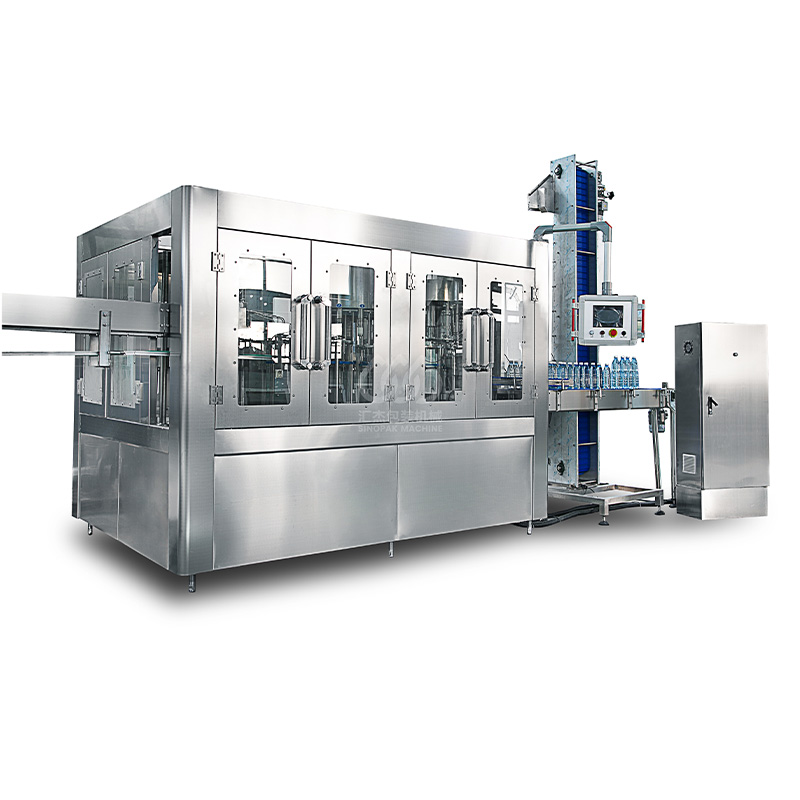

Factory source Water Bottling Plant - Glass Bottle Liquor Alcohol Filling Machine – SINOPAK

Factory source Water Bottling Plant - Glass Bottle Liquor Alcohol Filling Machine – SINOPAK Detail:

Adopting the bottle bottom holding type to send bottles into filling machine through bottle inlet screw via thrum bottle star wheel, and then the bottles will be held by lifting device, and achieve up and down under the function of lifting cam and down pressure cam. The filling model is precisely filling. After bottle mouth raises to contact valve and open valve, then starting to filling; when finish filling, the bottle mouth falls and leaves valve, also bottle is leading-out filling machine by bottle holding type, and conveyed to convey chain by thrum bottle star wheel.

◆ This machine has a compact structure, perfect control system, easy to operate and highly automated.

◆ The parts contact with product is made of quality SUS, anti-corrosive, and easy to clean.

◆ By adopting high speed filling valve, the liquid level is precise and no waste. That guarantees the demand of filling technology.

◆ Only by changing the bottle block, star-wheel, can realize to fill the changed bottle shape.

◆ The machine adopts perfect overload protective device can ensure the operator and machine safe.

◆ This machine adopts frequency converter, which can adjust the capacity suitably.

◆ The main electric components, frequency, photoelectric switch, proximity switch, electric control valves all adopt imported components, which can ensure the quality performance.

◆ The control system has many functions, such as control producing speed, and production counting etc.

◆ The electric components and pneumatic components are all introduced from world famous brand products.

|

Model |

Washing Heads |

Filling Nozzle |

Capping Heads |

Dimension mm |

Power kw |

Capacity BPH |

|

VXGF 14-12-5 |

14 |

12 |

5 |

2380*1750*2350 |

2 |

3000 |

|

VXGF 24-24-8 |

24 |

24 |

8 |

2860*2230*2350 |

3 |

6000 |

|

VXGF 32-32-8 |

32 |

32 |

8 |

3500*2650*2350 |

4.7 |

8000 |

|

VXGF 40-40-10 |

40 |

40 |

10 |

3800*2950*2350 |

7.5 |

12000 |

|

VXGF 50-50-12 |

50 |

50 |

12 |

5900*3300*2350 |

9 |

15000 |

Product detail pictures:

Related Product Guide:

Bear Customer initially, High quality first in mind, we do the job closely with our customers and supply them with efficient and skilled providers for Factory source Water Bottling Plant - Glass Bottle Liquor Alcohol Filling Machine – SINOPAK , The product will supply to all over the world, such as: Morocco, Bulgaria, Paraguay, We've got constructed strong and long co-operation relationship with an enormous quantity of companies within this business in Kenya and overseas. Immediate and professional after-sale service supplied by our consultant group has happy our buyers. Thorough Info and parameters from the merchandise will probably be sent for you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Kenya for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.