Factory For Fully Automatic Blow Moulding Machine - Electrical Servo Type Drinking Water Bottle Blowing Molding Machine – SINOPAK

Factory For Fully Automatic Blow Moulding Machine - Electrical Servo Type Drinking Water Bottle Blowing Molding Machine – SINOPAK Detail:

1. Feeding system:

1)Continous and high speed preform feeding system.

2)No pneumatic claws were used, feeding faster, no air claws changing required, less part changing cost in future.

3) Multiple protection device for precise preform feeding.

2. Trasfer and heating system:

1) Horizontal rotation transfer style, no preform turnover, simple structure.

2) Compact preform-chain pitch design for efficient heating and reduce energy consumption.

3)Cooling channel applied in heating tunnel to guarantee no deform of preform neck.

4)Optimized ventilation to ensure heating consistency.

5) With function of preform temperature detection.

6)Easy access for heater maintenance and lamp changing.

3. Transfer and bottle out system:

1)Servo motor driven preform transfer system for quick transfer and precise preform locating.

2)No pneumatic clampers were used for bottle taking out, less maintenance in future, less running cost.

4. Stretching blowing and molding system:

1)Servo motor driven system with synchronized base blow mould for fast response operation.

2)Precision electromagnetic blowing valve group for fast and high productivity.

5. Control system:

1)Touch-panel control system for simple operation

2)Simens controlling system and servo motors, better system used.

3)9 inch LCD touch screen with 64K colors.

6. Clamping system:

No link rod,no toggle structure, simple and reliable servo clamping system. Less maintenance in future.

7. Others:

1)All electric mechanism to ensure high-speed operation and precise locating.

2)Design for quick mould change.

3)Less with high pressure recycle system, no separate low pressure input required.

4)Low energy consumption, low wear, more clean structure.

5)Easy directly connect to filling production line.

|

Model |

SPB-4000S |

SPB-6000S |

SPB-8000S |

SPB-10000S |

|

Cavity |

4 |

6 |

8 |

10 |

|

Output(BPH) 500ML |

6,000 pcs |

9,000 pcs |

12,000 pcs |

14000pcs |

|

Bottle size range |

Up to 1.5 L |

|||

|

Air consumption(m3/minute) |

6 cube |

8 cube |

10 cube |

12 |

|

Blowing pressure |

3.5-4.0Mpa |

|||

|

Dimensions (mm) |

3280×1750×2200 |

4000 x 2150 x 2500 |

5280×2150×2800 |

5690 x 2250 x 3200 |

|

Weight |

5000kg |

6500kg |

10000kg |

13000kg |

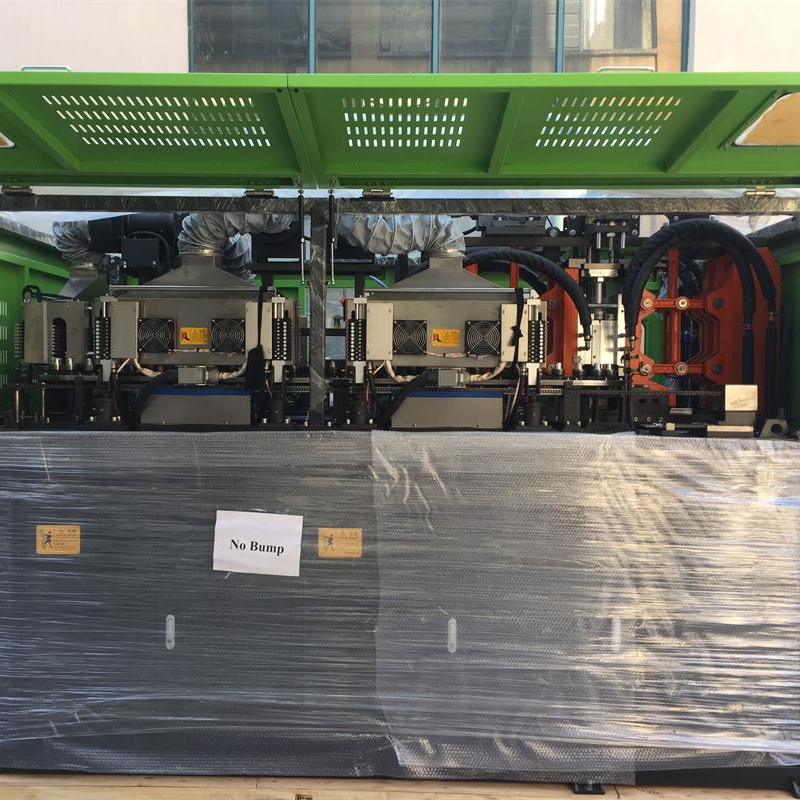

Product detail pictures:

Related Product Guide:

In the past few years, our business absorbed and digested advanced technologies both equally at home and abroad. In the meantime, our company staffs a group of experts devoted to your advancement of Factory For Fully Automatic Blow Moulding Machine - Electrical Servo Type Drinking Water Bottle Blowing Molding Machine – SINOPAK , The product will supply to all over the world, such as: Kenya, Mexico, Islamabad, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. We also offer agency service---that act as the agent in china for our customers. If you are interested in any of our products or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!